Thoughts on Stage Floors

Let's talk about stage floors for a moment because they don't always get the attention they deserve. The floor of the stage serves two important purposes: it's the working surface for performers and it's the attachment surface to brace or lock down scenery. These functions have very different requirements, but both have to be worked into the floor design. Here's why. Unlike the floor in a home or office the stage floor needs to provide cushion for performers who, as part of the performance, may be:

Jumping

Jumping and landing on body parts other than their feet

Stage fighting

Dancing

Rolling

Acrobatics

Sure, performers can do this once on a hard floor once but doing it over and over in rehearsal and then for eight shows a week can really take its toll on their bodies. Injuries can end performances and careers, so the floor's ability to absorb impact is critical. Equally important, especially for dance and acrobatics, is the floor's ability to return the energy of the impact so performers spring off of the floor into their next movement, not sink into it. This is called resiliency.

How do we design a resilient floor? The simplest, but least resilient floor, is just rubber pads under plywood. The plywood is usually topped with Masonite, as shown below.

Section of simple stage floor

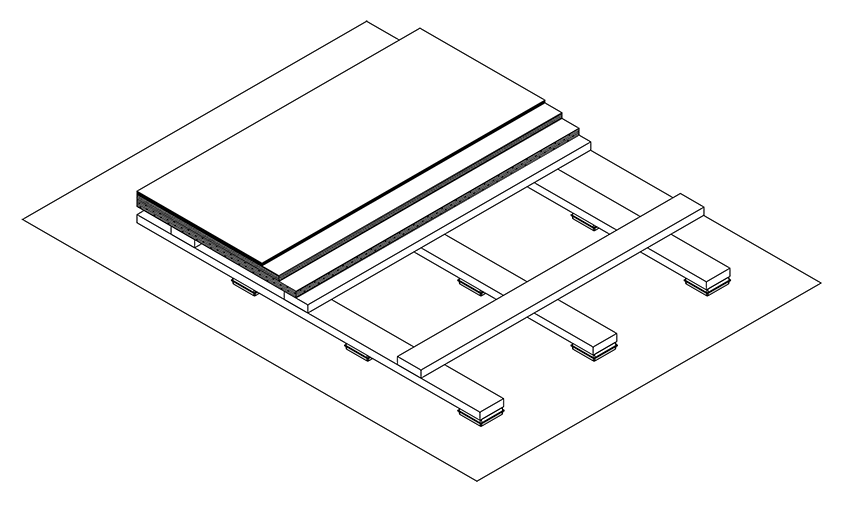

A system that provides more resilience adds one or two layers of sleepers between the pads and the plywood.

section of resilient stage floor

When a highly resilient floor is needed, such as in a dance theatre, we turn to a basket weave with several layers of sleepers between the rubber pads and the plywood.

Some manufacturers offer pre-fabricated systems that use one or more layers of foam in place of the rubber pads and/or sleepers. These systems cost more in materials but may save money in labor.

Why do we need so much plywood (at least 2 layers of ½”) on top? It’s to satisfy the second requirement, a solid layer to screw or nail into. As the image below (from the web site of IATSE 470) shows, tall pieces of scenery are braced from behind and those braces are screwed or nailed into the stage floor.

Platforms on stage are often locked into place with L-irons screwed into the floor. There can be a lot of force applied to scenery during a performance and we don’t want the nails or screws pulling out of the floor, so we need a thick layer of solid material that screws and nails can bite into.

So, for architects who ask why we can't just have sealed concrete or some other simple, inexpensive floor - now you know.

Any questions? Just ask.